.

Inther Group: improving intralogistics

Inther Group is een internationale system integrator, gespecialiseerd in automatiseringsoplossingen voor magazijnen. Wij leveren en onderhouden systemen voor het verzamelen, verpakken, opslaan en sorteren van goederen, gebaseerd op het modulaire en uiterst flexibele Inther LC Warehouse Execution System. Inther onderscheidt zich door zijn holistische benadering. Van analyse, ontwerp, realisatie en oplevering tot 24/7 service en support wereldwijd. Wij zijn een full service partner voor uw intralogistiek.

Central Filling is a hybrid process that allows orders to be fulfilled at the patient or prescription level. This process is particularly suitable for the pharmaceutical industry, because orders no ...longer have to be put together at the pharmacy, savings lots of time, personnel and money. In addition, Central Filling provides extra accuracy through a 100% control and contributes to efficiency through the integrated FMD dispensing.Show More

Inther Group's Central Filling for pharma

Central Filling is a hybrid process that allows orders to be fulfilled ...

Central Filling is a hybrid process that allows orders to be fulfilled at the patient or prescription level. This process is particularly suitable for the pharmaceutical industry, because orders no ...longer have to be put together at the pharmacy, savings lots of time, personnel and money. In addition, Central Filling provides extra accuracy through a 100% control and contributes to efficiency through the integrated FMD dispensing.Show More

A Solid Guarantee for the On-Time Supply of Spare Parts

Inther Group's intralogistics optimization project in the automotive ...

Inther Group's intralogistics optimization project in the automotive sector has elevated storage processes and production shipping dynamics for BMW. Through modern conveyor systems, automated small parts warehousing with agile shuttles, ...and ergonomically tailored order-picking stations, Inther Group has unlocked new throughput potential, ensuring timely delivery of spare parts with enhanced quality and dependability.Show More

Westfort IJsselstein project overview | Inther Group

Inther Group automated the frozen meat process at Westfort in ...

Inther Group automated the frozen meat process at Westfort in IJsselstein, the Netherlands, a.o. with a shuttle system operation in a deep-frozen environment (-23°C).

This individual storing in a shuttle ...system in a frozen environment on location reduces transportation and CO2 emissions, while simultaneously reducing cycle times and thus stock inventory and time to market. The automated Inther frozen meat logistics process also leads to fewer errors and increased safety.Show More

Inther Group | Intralogistikprozess für Tiefkühlfleisch

Das von Inther optimierte Tiefkühl-Intralogistikmodell ist viel ...

Das von Inther optimierte Tiefkühl-Intralogistikmodell ist viel effizienter als der herkömmliche Prozess für Tiefkühlfleisch, bei dem Produkte manuell auf Paletten gelegt und eingefroren werden und mehrere Transporte zwischen verschiedenen Standorten ...erfordern.

Durch das Einfrieren und Lagern einzelner Kartons in einem Inther-Shuttle-System in einer Tiefkühlumgebung vor Ort, bis eine Palette vollständig ist und automatisch kommissioniert und palettiert wird, können mehrere Vorteile erzielt werden, wie zum Beispiel:

- Energieeinsparung bis zu 22 %

- Weniger Feuchtigkeits- und Gewichtsverlust der Produkte

- Verkürzung der Zykluszeit durch geringere Lagerbestände und kürzere Markteinführungszeiten

- Weniger Transport = weniger CO2-Emissionen

- Bis zu 8 % mehr Lagerraum in jedem 20-Fuß-Container

- Weniger Fehler und Unfälle durch Automatisierung des Prozesses

Möchten Sie herausfinden, was unsere Automatisierung sonst noch für Sie tun kann?

Besuchen Sie inthergroup.de/frozenmeatShow More

Inther Group | Tiefkühlfleisch Intralogistikprozess Animation

Das von Inther optimierte Tiefkühlfleisch-Intralogistikmodell ist viel ...

Das von Inther optimierte Tiefkühlfleisch-Intralogistikmodell ist viel effizienter als der herkömmliche Prozess für Tiefkühlfleisch, bei dem Produkte manuell auf Paletten gelegt und eingefroren werden und mehrere Transporte zwischen verschiedenen Standorten ...erfordern.

Durch das Einfrieren und Lagern einzelner Kartons in einem Inther-Shuttle-System in einer gefrorenen Umgebung vor Ort, bis eine Palette vollständig ist und automatisch kommissioniert und palettiert wird, können mehrere Vorteile erzielt werden, wie zum Beispiel:

- Energieeinsparung bis zu 22 %

- Weniger Feuchtigkeits- und Gewichtsverlust der Lebensmittel

- Verkürzung der Zykluszeit durch geringere Lagerbestände und kürzere Markteinführungszeiten

- Weniger Transport = geringere CO2-Emissionen

- Bis zu 8% mehr Lagerraum in jedem 20-Fuß-Container

- Weniger Fehler und Unfälle durch Automatisierung des Prozesses

Möchten Sie herausfinden, was unsere Automatisierung sonst noch für Sie tun kann? Besuchen Sie http://www.inthergroup.de/frozenmeatShow More

Inther Group | Frozen Meat intralogistics process

The Inther optimized freezing intralogistics model is much more ...

The Inther optimized freezing intralogistics model is much more efficient than the conventional frozen meat process, where products are manually put and frozen on pallets with multiple transports between different ...locations.

With individual carton freezing and storing in an Inther shuttle system in a frozen environment on location, until a pallet is complete and picked and palletized automatically, multiple benefits can be achieved, like:

- Energy savings up to 22%

- Less moisture & weight loss of the food

- Cycle time reductions with less stock inventories and a shorter time to market

- Less transportation = less CO2 emissions

- Up to 8% more storage in each 20ft container

- Fewer errors and accidents due to automation of the process

Want to find out what else our automation can do for you?

Visit sub-zero-solutions.comShow More

Inther Group | Frozen Meat intralogistics process animation

The Inther optimized freezing intralogistics model is much more ...

The Inther optimized freezing intralogistics model is much more efficient than the conventional frozen meat process, where products are manually put and frozen on pallets with multiple transports between different ...locations.

With individual carton freezing and storing in an Inther shuttle system in a frozen environment on location, until a pallet is complete and picked and palletized automatically, multiple benefits can be achieved, like:

- Energy savings up to 22%

- Less moisture & weight loss of the food

- Cycle time reductions with less stock inventories and a shorter time to market

- Less transportation = less CO2 emissions

- Up to 8% more storage in each 20ft container

- Fewer errors and accidents due to automation of the process

Want to find out what else our automation can do for you?

Visit sub-zero-solutions.comShow More

Inther Group LogiMAT 2024 Aftermovie

What makes Inther Group stand out from the ordinary intralogistcs ...

What makes Inther Group stand out from the ordinary intralogistcs supplier?

Our main advantage is our attitude. In the last 25 years we have come to understand all too well that ...personal connection and a dash of fun are the things that inspire us to always go the extra mile for our customers.

Just ask those who stopped by our booth at LogiMAT 2024 or watch our aftermovie and discover the Inther difference.Show More

Uniphar Group project overview | Inther Group

Inther Group has set up a completely new automated warehouse for ...

Inther Group has set up a completely new automated warehouse for global pharmaceutical partner Uniphar Group in Annacotty, Ireland. The solution includes an A-Frame, Miniload and an automated packaging line. ...With this project, Uniphar Group has access to a modern system for the delivery of orders to their customers. The delivery time is shortened and the supply chain is made redundant.Show More

Testimonial Service Account Manager

Testimonial Service Account Manager

Testimonial Service Account Manager

Testimonial Installation Engineer

Testimonial Installation Engineer

Testimonial Installation Engineer

Testimonial Software Engineer

Testimonial Software Engineer

Testimonial Software Engineer

A-Frame | Inther Group

The A-Frame is a fully automatic order picking solution for the quick ...

The A-Frame is a fully automatic order picking solution for the quick processing of complex orders. This 'proven technology' is used, among other things, in pharmaceutical distribution.

Testimonial Project Manager Inther Group

Who can tell you about the work at Inther better, than the employees ...

Who can tell you about the work at Inther better, than the employees themselves? In our series 'The people of Inther', Intheraars tell you all about their experiences at Inther ...Group. Curious? Check out the story of Edwin Heijnen who tells you all about his experience working as a Project Manager at Inther Group!Show More

Testimonial Site Supervisor Inther Group

𝐓𝐡𝐞 𝐩𝐞𝐨𝐩𝐥𝐞 𝐨𝐟 𝐈𝐧𝐭𝐡𝐞𝐫 Who can tell you about the work at Inther better, ...

𝐓𝐡𝐞 𝐩𝐞𝐨𝐩𝐥𝐞 𝐨𝐟 𝐈𝐧𝐭𝐡𝐞𝐫

Who can tell you about the work at Inther better, than the employees themselves? In our series 'The people of Inther', Intheraars tell you all about their ...experiences at Inther Group. Curious? Check out the story of Gido Mooren who tells you all about his experience working as a Site Supervisor at Inther Group!Show More

Inther Group Central Filling project at Pluripharm

In the past period, system integrator Inther Group has implemented one ...

In the past period, system integrator Inther Group has implemented one of its hybrid solutions, Central Filling, at pharmaceutical wholesaler Pluripharm Groep. With this solution, Pluripharm Groep can further unburden ...its customers because processing of recipes now takes place in an even more efficient way. In this video we will tell you more about the process of implementation, the collaboration and the results for Pluripharm.Show More

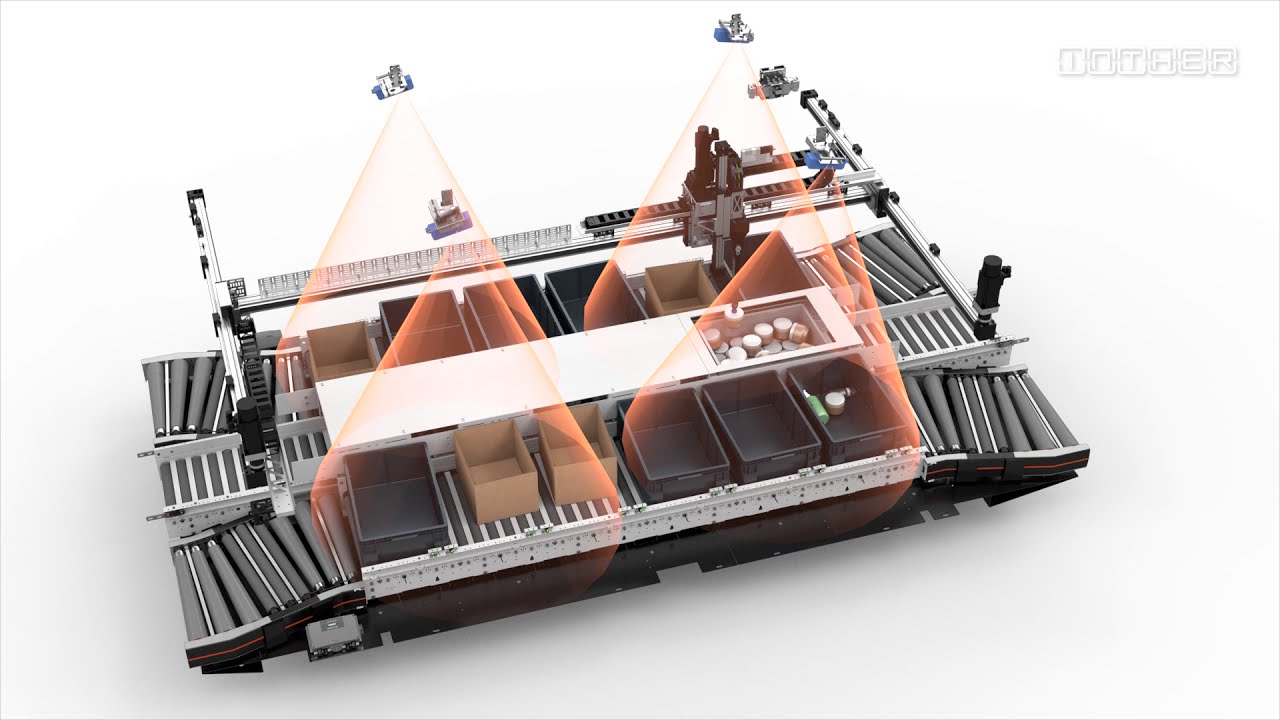

GRIPP 3/4: Unique selling points of GRIPP

When it comes to details, we strive for perfection. This innovation ...

When it comes to details, we strive for perfection. This innovation will make a difference in your logistic process. Joep Brauer, Product Owner of GRIPP, will guide you through the ...unique selling points of GRIPP.

Curious to learn more about GRIPP and how it can improve your process? Watch the mini-series about this exciting innovation!Show More

GRIPP 2/4: The idea for GRIPP is born

Mini series: GRIPP Curious to learn more about GRIPP and how it can ...

Mini series: GRIPP

Curious to learn more about GRIPP and how it can improve your process? Watch the mini-series about this exciting innovation!

With up to 1200 picks per hour and AI ...technologie, GRIPP is one of our most exciting innovations. In this second part of the series, our CTO Mike Strijbos will tell you how the idea for GRIPP was born and how this innovation can improve your process.Show More

GRIPP - Gantry Robotic Intelligent Piece Picker | Inther Group

GRIPP 1/4: Innovation and Inther Group

Mini series: GRIPP Innovation is in the DNA of Inther Group. This has ...

Mini series: GRIPP

Innovation is in the DNA of Inther Group. This has led to the development of GRIPP, Gantry Robotic Intelligent Piece Picker. In the first part of the series, ...our CEO Martijn Herder will introduce you to Inther Group and explain why innovation is so important to us!

Curious to learn more about GRIPP and how it can improve your process? Watch the mini-series about this exciting innovation!Show More

HEMA e-commerce DC | Inther Group

In four years, HEMA has increased the capacity of the e-commerce DC ...

In four years, HEMA has increased the capacity of the e-commerce DC from 80,000 to 130,000 picks per day. To realize this, Inther Group has designed and built a largely ...automated order picking system. The solution includes a miniload and shuttle system, supplemented with smart software for optimal distribution of the workload.Show More

CT01 Roller Conveyor Alignment 24V | Inther Conveyor Equipment

The CT01 Roller Conveyor Alignment 24V aligns materials to the left or ...

CT01 Roller Conveyor Curve 24V | Inther Conveyor Equipment

The CT01 Roller Conveyor Curve 24V transports materials automatically ...

The CT01 Roller Conveyor Curve 24V transports materials automatically using a programmed controller. Each zone is driven by a motor roller that drives the non-driven rollers by means of belting.

https://www.inthergroup.com/products/conveyor/